Unagi, Deconstructed: How An E-Scooter Works

It’s not magic. It might look like a bespelled work of Byzantine machinery unearthed, reformed, and refitted for a new age, but the electrical chariots of modernity are powered by ions, not alchemy. To satisfy the voracious cravings of our technologically Dionysian ridership, we decided to reveal some of the mechanisms that put motion into your Unagi.

From a sound structure, to an intelligent controller, to an efficient nervous system, there are many variables that must be balanced to create a competitive electric scooter. Increasing range, top speed, and acceleration all come at a cost. Although the pieces might seem complicated individually, and near incomprehensible when combined, one might be able to comprehend the elements and their relations when assessing each in their respective groupings. As is the basis of all things, from subatomic to colossal, let us begin with structure.

In creating any electric scooter, designers, manufacturers, and technologists will place a great deal of care into sourcing and combining the best materials for their respective jobs. While some metals offer strength and integrity, others offer flexibility. Some metals may offer the correct balance of pliability and load capacity, but, because of their weight, might add too much bulk to the scooter. Others might make for an incredibly lightweight device, but produce too brittle a frame. These considerations were batted back and forth until the correct balance of materials was arrived at to create the Model One.

The shaft of our electric scooter is made of carbon fiber, fibers 5-10 micrometers in diameter made up of carbon atoms. Similar to graphite in atomic structure, carbon fiber consists of sheets of carbon atoms arranged in a hexagonal pattern. This pattern is what gives carbon fiber its strength, as opposed to the fragile, parallel stacking pattern of carbon sheets in graphite. In addition to tensile strength, this hexagonal arrangement produces beneficial characteristics that include high stiffness, low weight, and high temperature tolerance. Because of these properties, it is common to find carbon fiber used in a range of fields of engineering, including civil, aerospace, and automotive. For our shaft, we chose to use carbon fiber to limit weight above the center of gravity, the amount of which effects motion, without compromising stiffness.

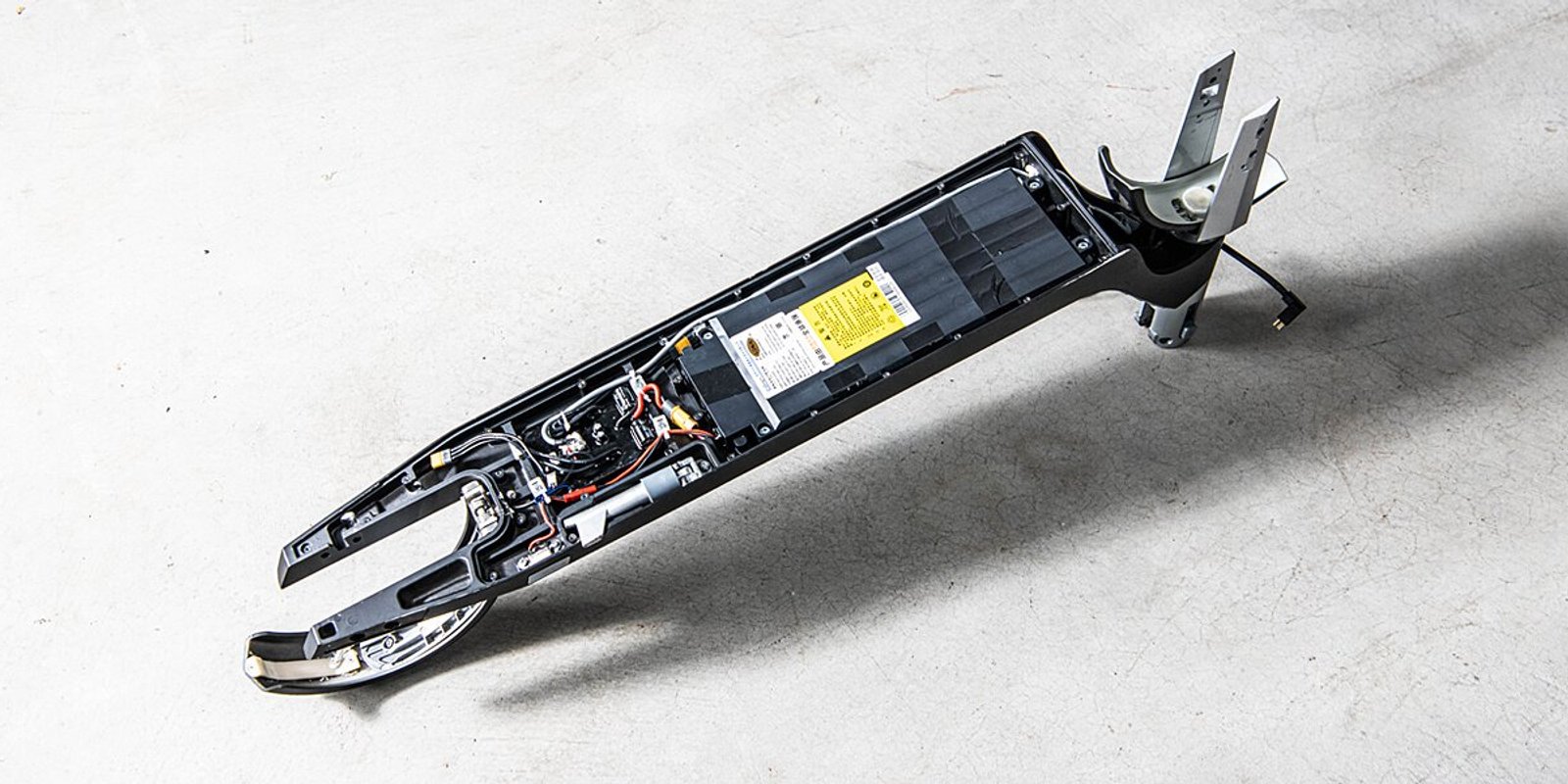

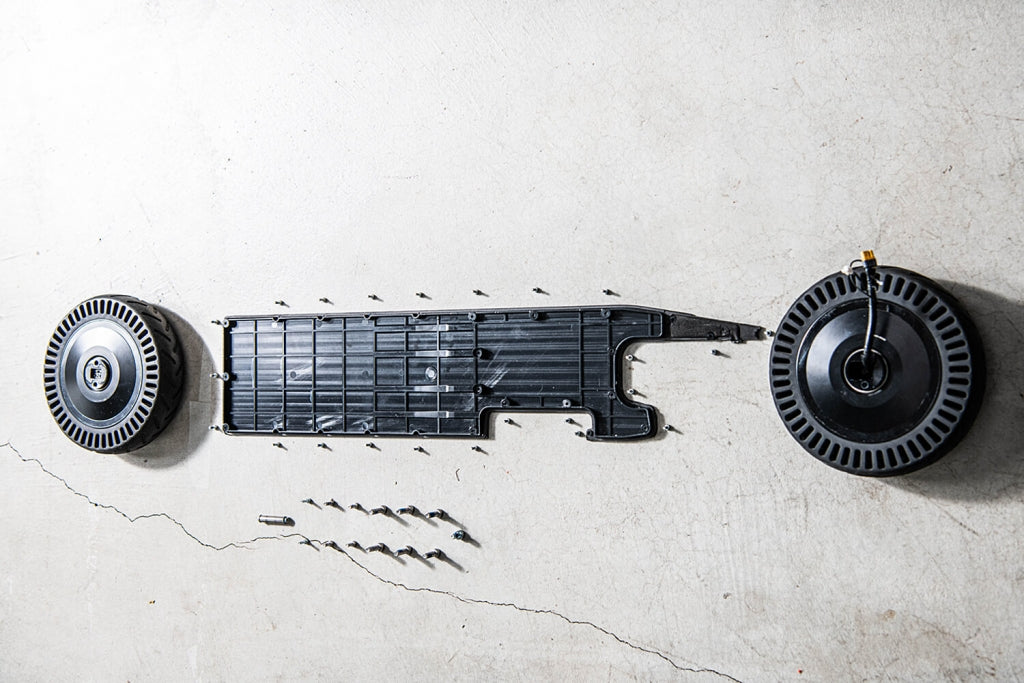

The deck of the Unagi Model One is made of a special aluminum alloy that allows for enough rigidity to hold together the electrical components located there-in without being brittle enough to snap under the weight of the rider. Additionally, the milling process of the deck was also refined to minimize weight while maximizing strength. Like the selection of carbon fiber for use in our shaft, the decision to use aluminum alloy for our deck came as the product of a fine balancing act.

Our one click folding mechanism is a critical part of The Model One’s construction, allowing for the easy portability on which we pride ourselves. It also packs a great deal of functionality into one space. The mechanism both locks the front wheel in place when folded and allows for a one-click fold when open. The core of the device is an aluminum casing which houses a stainless steel machined rod.

Another critical part of the Model One’s structure, its handlebar, is made from an aluminum/magnesium alloy. Although the strength-to-weight ratio of magnesium alloys is comparable to those of strong alloys of steel, magnesium alloys have a lower density, higher load per unit weight capacity, and produce higher stiffness while maintaining a light weight. Because of the amount of casting and machining our handlebars are subject to prior to finish, the strength-to-weight and stiffness of magnesium is critical to construction. Now that you understand a bit about our structure, let’s talk about the user interface and drivetrain, both components that allow the user to put his or her scooter into motion.

When a rider pushes down on the Unagi’s throttle, our control interface checks to see if the scooter is in motion (our kick-to-start safety feature), and, if in motion, translates your input - pressure on the throttle - into data which in turn determines the amount of power distributed to the in-wheel-motor. Due to our throttle’s built in modulation, rider’s have especially sensitive control over the scooter’s acceleration. In the case of our dual motor electric scooter, the controller detects whether dual mode is activated, and, if so, distributes power equally to both wheels. Our hub motors lock the center or each motor to the fork or chassis with their axels so that when electricity is run through them, the magnets in the outer portion repel the tightly coiled wire in the middle to create motion.

When a top-speed setting is engaged, and that speed is reached, our controller reduces the amount of power relayed to both wheels to maintain that top speed. Similarly, if, for whatever reason, the controller senses overheating or stalling, it will reduce power to the motors to avoid damage to the battery or motor. The controller also governs braking. In our dual motor model - even when dual motor mode isn’t active – the controller will send an electrical signal to brake both wheels when engaged. In our single motor model, only the back wheel receives the braking response from our control unit. In additional to electric braking, our back wheel is outfitted with a friction brake that has been designed to prevent excessive wearing of the tire or the underside of the brake, allowing for near indefinite use.

To power our scooter, we decided to use an 18650 lithium-ion battery provided by our friends at LG. In lithium-ion batteries, the ions move from the negative electrode through an electrolyte to the positive electrode during discharge, and back to the negative electrode when charging. These batteries have high energy density, low self-discharge, and are cost effective. This battery is the source of the electricity transmitted to and relayed through our control unit to both motors.

Now that you’ve learned a bit about the mechanism, composition, and functionality of our scooter, go ahead and take your Unagi out for a spin! After a bit of thought, you might find our structural and electrical balancing act to border on the magical after all. To contribute to our community page, please email news@unagiscooters.com and tell our editors about your ideas and suggestions!